Automated Biomass Plants up to 35MW

COMPLETE SURVEY, DESIGN, PERMITTING, CONSTRUCTION and SERVICE from one place

High-performance, automated biomass systems

Sustainable, renewable energy for the future

According to the circular approach, locally produced biomass with significant calorific value, even from own farming, as a renewable energy source that is regenerated year after year, can ensure economical and efficient operation independent of service providers. The resulting ash with a high mineral content can be mixed with liquid fertilizer and returned to the farmland, thus reducing the need for fertilizers.

Our biomass systems - thanks to the high calorific value of straw and other biomasses - are capable of high energy production, and compared to the cost of fossil fuel (gas), they result in significant savings and quick payback. Solutions can be adapted to individual customer needs thanks to special system components. Dry and wet fuel can be used in boilers, with a water content of up to 60%. The size of the systems ranges from 250 kW to 35 MW, we offer turnkey, prefabricated solutions up to 35 MW. All of our projects are designed to operate as efficiently as possible with low emissions and minimal maintenance.

Areas of use

AGRICULTURE

pig farms, broiler farms, other livestock farms

horticulture, greenhouses, crop dryers, small family factories

INDUSTRY

food industry, processing industry, energy industry (biogas), service industry

INSTITUTIONAL AND DISTRICT HEATING

district heating power plants, budget plants, schools, kindergartens

Warm or hot water and steam systems

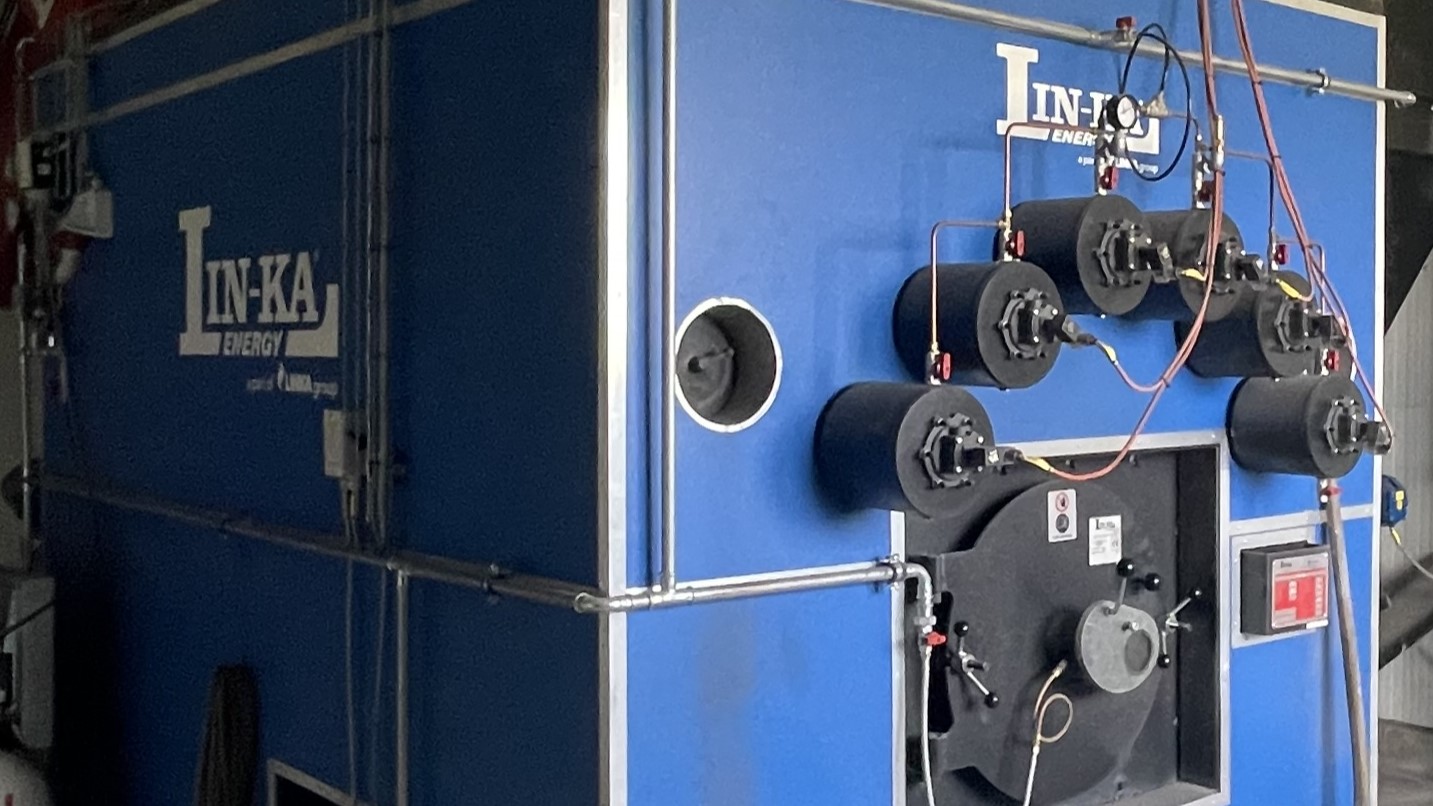

Exclusively distributed biomass boilers are capable of high energy output, as straw and other biomass provide a high calorific value. The system converts the biomass into a significant amount of energy within the boiler. Biomass boilers are usually designed for a hot water system with an operating pressure of 4 bar. However, these systems are designed to be suitable for steam production as well, and can provide an operating pressure of up to 90 bar for the processing industry and other industrial players.

The systems can be installed in a fixed or containerized, i.e. mobile, design.

Fuel types

Our boiler systems have been tested for many fuels in accordance with EU regulations, including several special fuels. In addition to straw, wood chips, and wood pellets, it is also suitable for burning other materials: among others, shavings, bark, twigs and cuttings, wood waste, wood shavings, hay, and stone fruits.

With locally produced fuels, facilities can produce sustainable heat for local use – the cleanest form of energy cycling. The essence of carbon dioxide or carbon neutrality is that during the use/burning of biomass, the same amount of carbon dioxide is released into the air as was absorbed by the plant during its life. And the newly planted plant absorbs the carbon dioxide again.

Our systems can operate efficiently even with the simultaneous burning of several types of fuel!

Fully automatic

Electrical control and monitoring

The system is completely controlled by a PLC control system. This system also controls the boiler to work optimally. System monitoring can be performed entirely remotely.

Automated feeding and dosing systems

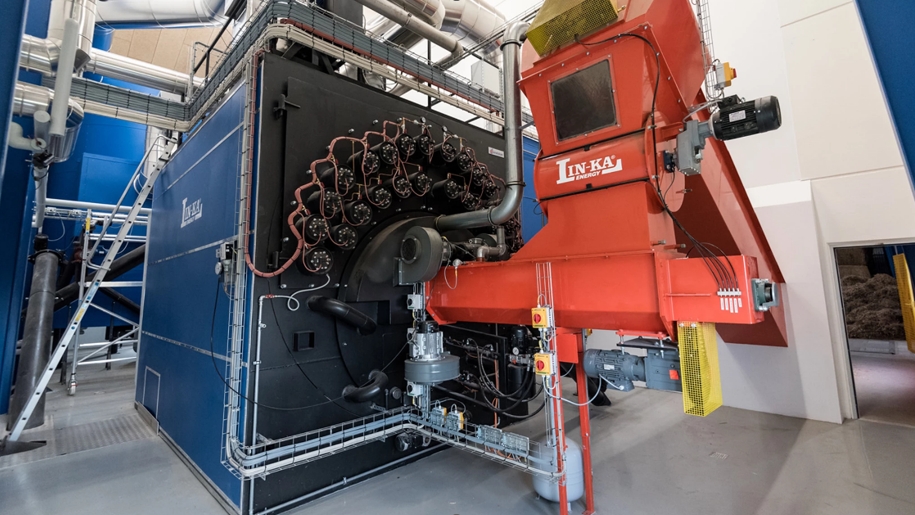

For straw and other baling systems, fuel is fed in using an automatic conveyor belt with a special bale chopper.

For straw and other baling systems, fuel is fed in using an automatic conveyor belt with a special bale chopper.

In the case of wood chips and other granular fuel, the fuel is brought into the boiler's firebox using a screw system from indoor or outdoor storage.

In the case of larger systems, we can also use a hall crane and a moving floor in combination with a special bale slicer.

The safe and efficient dosing of fuel into the combustion chamber of the boiler is ensured by a cell seal, which, in addition to supplying the unit of fuel, also ensures backburn prevention.

Automatic ash removal

A series of longitudinal and transverse stainless steel ashing screws placed under the fire grate, at the bottom of the boiler, moves the ash from the end of the boiler to an ash holding container, which can be located inside or outside the building, with the help of a rising copper screw line.

Automatic smoke and chimney cleaning

The flue pipes and chimney system of the boiler are continuously cleaned with an automatic, high-pressure compressed air cleaning system, thus minimizing the need for maintenance of the system. The plant can operate for up to 72 hours without human intervention!

In order to comply with sustainability and environmental regulations, special cleaning and efficiency-enhancing system elements are also installed:

economizer - heat recovery heat exchanger

multicyclone – heat recovery large particle filter

filter – fine solids filter

How can we help?

- Design

- License

- Construction

Biomass boiler systems up to 0,5 - 35MW

Biomass boiler systems up to 0,5 - 35MW